ept in the Automotive Industry

Family-operated and globally active

ept stands for electronic precision engineering. The quality of our products is particularly important to us, as fail-safe and reliable connectors are essential for human safety, especially in the automotive industry. As one of the last family-owned businesses with production in Germany, we supply our partners with highly sophisticated PCB connections in a customer-oriented manner.

Corporate History

1973 Bernhard Guglhör founded Bernhard Guglhör Präzisionsteile, a company based in Buching, Germany. It later became ept GmbH. Today, the family-run SMB is managed by his son, Thomas Guglhör, under the name ept GmbH and now has 1,200+ employees worldwide.

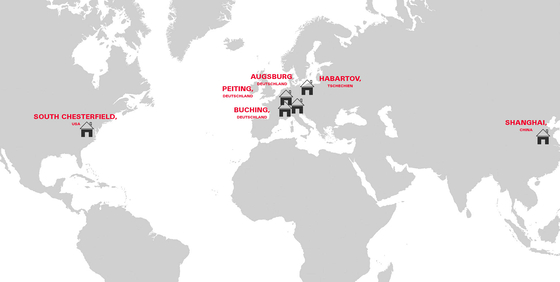

Sites

We are a manufacturer of all PCB connectors for automotive technology and a globally active company. ept GmbH has been based in Peiting, Germany, since 1979. In 1990, we established a sales office in the U.S. and just three years later a production facility in the Czech Republic. In 1995, it was decided that another production facility would be opened in Augsburg – the third in Germany by now – in order to meet the increasing demand. We were then able to gain a foothold in China as early as 1998 and set up a sales office there. The plant in the U.S. was expanded to include production facilities in 2008. The headquarters in Peiting now employs around 600 people.

- Buching, DE

- Peiting, DE

- Augsburg, DE

- Habartov, CZ

- Shanghai, China

- South Chesterfield, USA

Decades of Experience in the Automotive Industry

We have been developing end-to-end solutions for connectors in the automotive industry for nearly 50 years. This means that we not only manufacture the contacts, but also the insulation body, which is fitted with the contacts directly in-house.

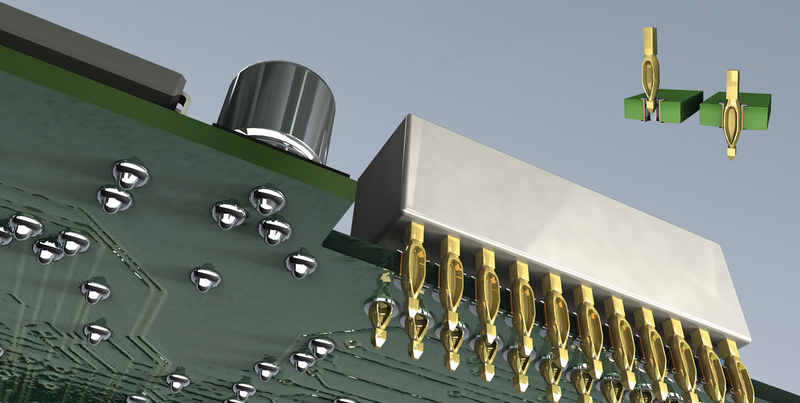

Tcom press® press-fit zone

Our Tcom press® press-fit zone provides full contact reliability at all times and is also an uncomplicated solder-free connection. We have already created many outstanding solutions for the automotive sector using this PCB connection technology.

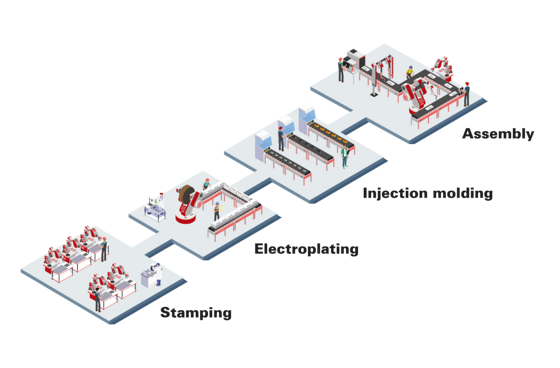

One-stop Supplier for the Automotive Industry

Four steps take place in our in-house production facilities before the finished connector is created: the stamping and galvanizing of the contacts as well as the injection molding and assembly of the insulation body. Our experienced designers and constructors as well as accurate toolmakers are responsible for the smooth development process. The custom-built, high-precision machines at ept also play a major role in our concept for success.

We offer you all manufacturing steps for automotive connectors under one roof as a one-stop supplier. This enables us to directly consider special customer requests and to oversee them precisely. For example, if our customer has a change request, we can review and approve it promptly. Subsequently, we can implement the change immediately. This makes us a flexible, customer-oriented one-stop supplier that has served many satisfied customers for decades.

We offer you all manufacturing steps for automotive connectors under one roof as a one-stop supplier. This enables us to directly consider special customer requests and to oversee them precisely. For example, if our customer has a change request, we can review and approve it promptly. Subsequently, we can implement the change immediately. This makes us a flexible, customer-oriented one-stop supplier that has served many satisfied customers for decades.

Decades of Experience in the Automotive Industry

Press-fit Technology

We have had particularly good experience with the requirements of press-fit technology in terms of gas-tightness and robustness. Press-fit connections have been in high demand in the automotive industry for many years. Our customers highly appreciate our long-term delivery availability and the always extremely high quality of our products, which for them is a decisive factor.

Process Experience in the Automotive Industry

Our advanced project management is based on the APQP (Advanced Product Quality Planning) process and has been producing excellent results for many years. We prepare a comprehensive bid with all the important data for you after receiving a technical customer inquiry. Once you have chosen us as your connector supplier, our experienced project managers will actively support you with their know-how and expertise. We provide you with the best possible support to optimize your connector and meet your requirements – from defining to developing the project, right through to launching production and managing after-sales activities.